Reinforced Cement Concrete | Purpose, Types , Uses, Advantages

Reinforced Cement Concrete (RCC) is one of the most widely used materials in the construction industry. It combines the strength of concrete with the tensile properties of steel, making it ideal for buildings, bridges, and various other structures. RCC plays a vital role in modern construction, ensuring durability and resilience against external forces like wind, earthquakes, and heavy loads. In this article, we will dive deep into the key aspects of RCC, explaining its components, uses, advantages, and design principles.

What is Reinforced Cement Concrete ?

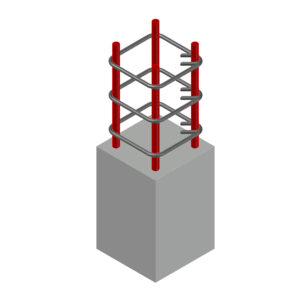

Reinforced Cement Concrete, often abbreviated as RCC, is a composite material made from a mix of concrete and reinforcing steel bars, also known as rebars. The primary components of RCC include cement, water, sand, and aggregates (such as gravel or crushed stones), but the critical addition that differentiates it from plain concrete is the steel reinforcement.

Key Components of RCC

- Cement: Acts as a binding agent, holding all the other ingredients together.

- Water: Initiates the chemical reaction needed to set and harden the cement.

- Sand and Aggregates: Provide bulk and strength.

- Steel Reinforcement: Reinforced cement concrete relies on steel bars to handle tensile stress. Steel and concrete bond well because they both expand and contract similarly when temperatures fluctuate.

Importance of Reinforcement in RCC

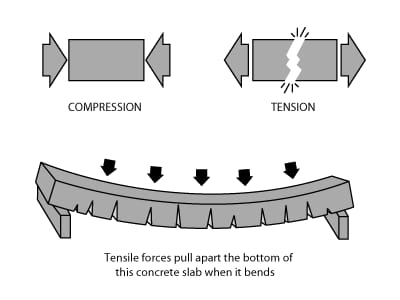

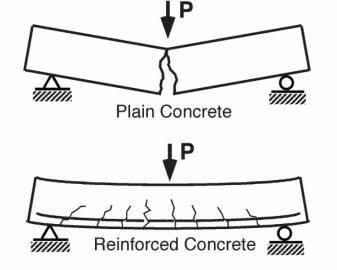

While concrete is very strong in compression, it is weak in tension. This is why steel reinforcement is added. The combination of these materials ensures that reinforced cement concrete performs well under both compressive and tensile stresses, making it suitable for a wide range of applications.

Importance of Reinforcement in RCC

The concept of reinforcing concrete with steel was first introduced in the mid-19th century. Joseph Monier, a French gardener, initially developed reinforced concrete for use in garden pots. Over time, the application of this technique expanded rapidly to cover large structures, including buildings, bridges, and dams. Reinforced cement concrete became the go-to material for both small and large construction projects because of its flexibility in design and durability.

Types of Reinforced Cement Concrete

There are several types of RCC based on the specific requirements of a project. Let’s explore the most common ones:

- Precast RCC: Precast reinforced cement concrete components are produced in a factory setting, ensuring consistent quality. These are then transported to the construction site.

- Cast-in-Situ RCC: This is the most commonly used RCC, where concrete is poured and cured on-site.

- Prestressed RCC: Here, high-strength steel cables or tendons are tensioned before or after the concrete is poured, allowing the structure to handle greater loads.

- Reinforced Lightweight Concrete: Used for specific applications where weight reduction is crucial without compromising strength.

Applications of Reinforced Cement Concrete

RCC is used in a wide variety of structures, from residential buildings to massive infrastructure projects.

- Buildings: Most modern buildings are constructed with reinforced cement concrete because it offers high strength and flexibility in design. Columns, beams, slabs, and footings all rely on RCC for stability.

- Bridges: Reinforced cement concrete is the material of choice for bridge decks and beams due to its ability to bear high loads and withstand environmental elements.

- Dams and Reservoirs: RCC is resistant to water, making it an ideal material for dams and water containment structures.

- Roads and Pavements: Reinforced cement concrete is used for laying durable road surfaces, especially in areas with heavy vehicular traffic.

Design Principles of Reinforced Cement Concrete

The design of RCC structures follows specific guidelines to ensure strength, stability, and safety. Engineers must carefully calculate the amount of reinforcement required based on the load the structure will bear. Some critical factors include:

- Load Calculation: This includes both dead loads (the structure’s weight) and live loads (furniture, people, vehicles).

- Shear and Bending Forces: Reinforced cement concrete must be designed to handle both shear forces (which can cause structural failure) and bending moments.

- Safety Factors: The design process includes various safety factors to accommodate unforeseen loads or material weaknesses.

- Code Compliance: All RCC designs must follow local building codes and regulations.

Advantages of Reinforced Cement Concrete

Reinforced cement concrete has several advantages over other building materials:

- Durability: RCC structures can last for decades with minimal maintenance, even under harsh environmental conditions.

- Fire Resistance: Reinforced cement concrete is non-combustible and performs well under high temperatures.

- Versatility: Reinforced cement concrete can be molded into virtually any shape or size, making it ideal for complex architectural designs.

- Cost-Effective: Given its strength and durability, reinforced cement concrete offers good value for money in the long run.

Disadvantages of Reinforced Cement Concrete

Despite its many benefits, RCC has some drawbacks that need to be considered:

- Initial Cost: The upfront cost of reinforced cement concrete can be high due to the need for skilled labor and materials.

- Weight: RCC is quite heavy compared to materials like steel or wood, which may require stronger foundations.

- Maintenance of Reinforcement: Over time, steel reinforcement can corrode if not properly protected, which can lead to structural failures.

- Long Construction Time: Curing and setting concrete can be time-consuming, extending project timelines.

Environmental impacts of Reinforced Cement Concrete

- High Carbon Emissions: Cement production is a major source of CO₂ emissions due to the energy-intensive processes and chemical reactions involved.

- Resource Depletion: Extracting raw materials like limestone, sand, and aggregates for cement can lead to the depletion of natural resources and habitat destruction.

- Energy Consumption: The production of RCC requires substantial energy, often derived from fossil fuels, contributing to greenhouse gas emissions.

- Waste Generation: The cement manufacturing process produces significant amounts of waste, including kiln dust and by-products, which need proper management or recycling.

To mitigate the environmental impact of reinforced cement concrete (RCC), adopting more sustainable practices is crucial. This includes using alternative materials such as fly ash, slag, or recycled aggregates to reduce the reliance on virgin resources and lower carbon emissions. Implementing energy-efficient technologies in cement production and transitioning to renewable energy sources can cut down on greenhouse gas emissions. Additionally, enhancing waste management and recycling processes can minimize environmental pollution and resource depletion. Promoting green building practices and innovations in concrete technology can further reduce the overall environmental footprint of RCC.

Maintenance of Reinforced Cement Concrete Structures

While reinforced cement concrete is generally low-maintenance, proper care is essential to extend its life. Here are some tips for maintaining RCC structures:

- Regular Inspections: Conduct periodic inspections to identify cracks, rusting of steel bars, or other signs of damage.

- Sealing: Apply waterproof sealants to prevent moisture from reaching the steel reinforcement.

- Timely Repairs: Address cracks and other structural issues as soon as they are detected to prevent further damage.

Innovations in Reinforced Cement Concrete

Advancements in technology continue to improve the performance of reinforced cement concrete. Some notable innovations include:

- Self-Healing Concrete: This type of reinforced cement concrete contains bacteria that activate when water enters cracks, producing limestone to seal the cracks.

- Fiber-Reinforced Concrete: Fibers (such as glass or steel) are added to the concrete mix, improving its tensile strength and reducing the need for traditional steel reinforcement.

- Green Concrete: Made from recycled materials, green reinforced cement concrete reduces the carbon footprint of construction projects.

- Fiber-Reinforced Polymer (FRP) Rebar: FRP rebars are non- corrosive, lightweight alternatives to steel reinforcement bars, They are commonly used in construction projects, especially in environments prone to corrosion, such as marine or chemical structures.

Fiber-Reinforced Polymer(FRP) Rebar

Conclusion

Reinforced Cement Concrete is a vital material in modern construction, offering a balance of strength, durability, and versatility. Its combination of concrete’s compressive strength and steel’s tensile strength makes it the preferred choice for projects ranging from skyscrapers to bridges. Although RCC has some challenges, such as weight and corrosion risks, its long-term benefits far outweigh the drawbacks. With ongoing innovations, reinforced cement concrete will likely remain a cornerstone of construction for decades to come.

Leave a Reply